This is an archived article that was published on sltrib.com in 2012, and information in the article may be outdated. It is provided only for personal research purposes and may not be reprinted.

Exelis, which produces parts for military and commercial aircraft, opened a design and manufacturing center in Salt Lake City facility Thursday that it hopes will bring more jobs to Utah in coming years.

Company officials, along with Gov. Gary Herbert and Congressman Jim Matheson, marked the occasion at the 250,000-square-foot facility on Amelia Earhart Drive in the International Center just west of the Salt Lake International Airport.

The new plant, which builds on to Exelis' existing 130,00-square-foot integrated structures center, was created from a strategy in which the company wants to produce more composite-material aircraft parts with automation. This initiative and new building have so far created 100 more jobs to go with Exelis' existing staff of 200. (Exelis has another, separate Salt Lake City plant that produces special acoustic sensors for the military and private companies).

"We made a commitment to this market, this community and this state," said Exelis CEO Dave Melcher.

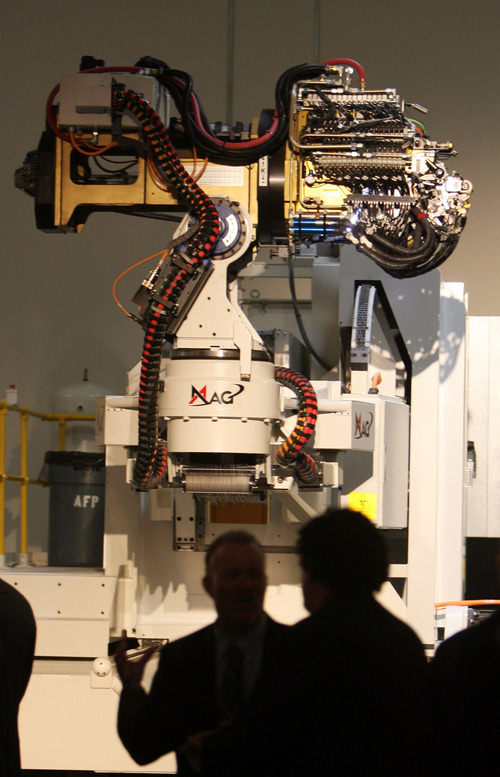

The new facility houses machinery that will produce, cut and inspect specialized airframe parts for aircraft such as Boeing's 7-series airliners and military aircraft such as the F-35 Joint Strike Fighter. Before, the parts were made by hand, although company officials said they have not had to lay off workers in the transition to automated machinery.

The parts are made of a composite fiber mixed with different types of resin to produce an aircraft piece that is 20 percent to 40 percent lighter but much stronger and stiffer than aluminum, said Exelis Vice President Mike Blair.

It's this transition from aluminum to composite materials that has created a demand for Exelis' work, Blair said. Commercial airlines, as well as the military, are demanding planes be made of composites to make them safer and to save on fuel costs.

"If you look at the composites industry, it's projected to grow from $4 trillion in composite assembly structures to nearly $12 trillion per year in about 10 years," Blair said.

Some of the aircraft parts that Exelis produces include water and waste tanks, and sections of the emergency slides for commercial airliners. It also makes tail-rotor pylons for the Marine Corp.'s CH-53K heavy-lift helicopter and access panels, special seals and wing skins for the F-35 jet, said James Barber, Exelis vice president and general manager.

Clients include Boeing, Airbus, GE Aviation (which makes aircraft engines), Orbital Science and Lockheed Martin, which produces the Joint Air-to-Surface Standoff Missile. "There's tons of potential work," Barber said of the new facility.

But Exelis officials could not say how many more jobs their new facility will help generate each year, although Gov. Herbert said he hopes it brings 2,500 more in the next 20 years.

"It all depends on the marketplace," Barber said.

Exelis, which spun off from ITT last year and became a public company, was slightly up in trading Thursday and closed at $10.68 a share. The company, headquartered in McLean, Va, has had operations in Salt Lake City for 40 years.