This is an archived article that was published on sltrib.com in 2011, and information in the article may be outdated. It is provided only for personal research purposes and may not be reprinted.

For SanSegal Sportwear owner Macon Rudick, only one thing is better than being able to market his products as environmentally friendly.

And that is being able to brag they also are "Made in the USA," while also contributing to an emergent revival of apparel making in this country.

"Today, a 'Made in the USA' label attracts a lot more buyers than being able to say that your products are 'green,' " Rudick said. "It sure doesn't hurt, though, if you can use both labels, especially in this economy."

Like many companies, Sandy-based SanSegal, which generates most of its revenue printing, silk screening and decorating T-shirts and other apparel for destination resorts and others in the tourism industry, was hard hit by the Great Recession.

Yet throughout the downturn and the subsequent weak recovery that followed, SanSegal's "Green Brand" remained one of the business's brights spots. Produced from recycled cotton fabric and polyester recovered from plastic bottles, the apparel line is cut, sewn and decorated at the company's 75,000-square-foot plant in Sandy, where 225 people are employed.

"It is our fastest-growing line, generating around 10 percent of our annual revenue," Rudick said, while acknowledging that most of the apparel and other items decorated by SanSegal are imported from Central American countries such as Honduras.

SanSegal — the name means "without equal" in French — was generating about $23 million in year in revenue prior to the recession. Sales fell to $12 million a year during the depths of the downturn but have since rebounded to around $18 million.

Joel Joseph, chairman of the Made in the USA Foundation, a California-based group that promotes American-made products in domestic and international markets, said from one perspective the Great Recession helped boost the success of many products produced domestically, from automobiles to sweatshirts.

"During the recession a lot of consumers started to realize the importance of this country's manufacturing base," he said. "And I think they became more aware of the products that are produced here and now are more willing to support the companies that make them."

Joseph said when he launched the Made in the USA Foundation in 1987 about 50 percent of the apparel purchased in this country was produced domestically. Now it is down to around 5 percent. "It's taken a big hit," he said.

Still, the apparel industry is slowly working its way back in the U.S. as evidenced by companies such as SanSegal and American Apparel, a clothing manufacturer, wholesaler and retailer that is based in Los Angeles and is known for its T-shirts and underwear.

"Although it can be a little more expensive to produce apparel in this country, there also is a lot mark-up in the industry. A pair of jeans might go for $200 in a major department store here but cost only about $20 to produce in China," Joseph said.

While most of the country's remaining apparel manufacturers are based in Los Angeles, Joseph said Utah would be a good place for such companies. "Wages are lower than in Los Angeles, and I would guess that land costs are cheaper, too."

Utah has been looked upon as an ideal place to operate such companies before.

In the 1960s, long before high-technology became the touchstone of the state's economic development efforts — and long before such terms as "aerospace industry cluster" and "software engineering" were commonplace — there was "stitch and sew."

The phrase harkens to a time when out-of-state clothing manufacturers poured into Utah, eager to set up operations to take advantage of a surplus of workers who could operate banks of sewing machines for comparatively low wages.

In the ensuing decades, though, what was once a thriving industry slowly faded under the relentless onslaught of cheap foreign competition. Twenty years ago, there were still as many 5,000 Utahns employed in the sewing industry.

"It was a low-skill area, which helps explain why it migrated overseas so easily," said Mark Knold, chief labor market economist for the Utah Department of Workforce Services.

Today, there are only about 1,200 Utahns in the sewing industry, working at 40 or so companies, he said.

Despite the decline, SanSegal owner Rudick believes better days are ahead and that the rebirth of the nation's apparel industry will begin with small companies that are nimble and can easily respond to the demands of the market.

"Over the past year and a half or so, we've been trying to concentrate more on the opportunities in the business-to-business market," he said.

So along with producing branded apparel for single-location destination resorts, SanSegal also is trying to expand its marketing toward new customers among the businesses with multiple locations — companies such as the Bubba Gump Shrimp Co. restaurant chain and Six Flags, the amusement park operator with more than a dozen locations.

One of the biggest draws for potential customers has been SanSegal's "Green Brand," which Rudick describes as offering some of the most eco-friendly garments in the world.

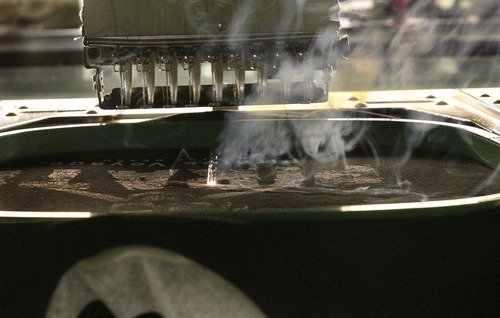

The cloth that goes into brand is produced from cotton remnants collected from sewing plants around the world. Those small scraps of fabric are bailed and shipped to a plant in Spain, where they are mixed with polyester fibers recovered from recycled plastic bottles. The resulting "mulch" is shipped to a plant in North Carolina, where it is spun into yarn and woven into a finished fabric.

For the past three years the Sundance Institute has been buying SanSegal's eco-friendly brand for sale at the various film festival venues, said Anne Peters, the institute's merchandising consultant.

"We wanted to buy from a Utah business and we love the local story," she said. "And because that apparel is made nearby, it has a lot smaller carbon footprint."

Other buyers of SanSegal's Green Brand include the Smithsonian Institution and many of the country's national parks.

Rudick says he can recall a time 33 years ago, about the time SanSegal got its start, when walking down Main Street in Park City he could see T-shirts and other branded apparel hanging in almost every store window.

"Now there are maybe only three stores there that have them on display. So there is a lot of opportunity for us even there."

Twitter: @OberbeckBiz —

Roomto grow

Unraveled industry • Twenty years ago, as many 5,000 Utahns were employed in the sewing industry. Today, there are only about 1,200.

Home-spun decline • In 1987, about 50 percent of the apparel purchased in the U.S. was produced domestically. Today, about 5 percent is.

Utah Department of Workforce Services and Made in the USA Foundation